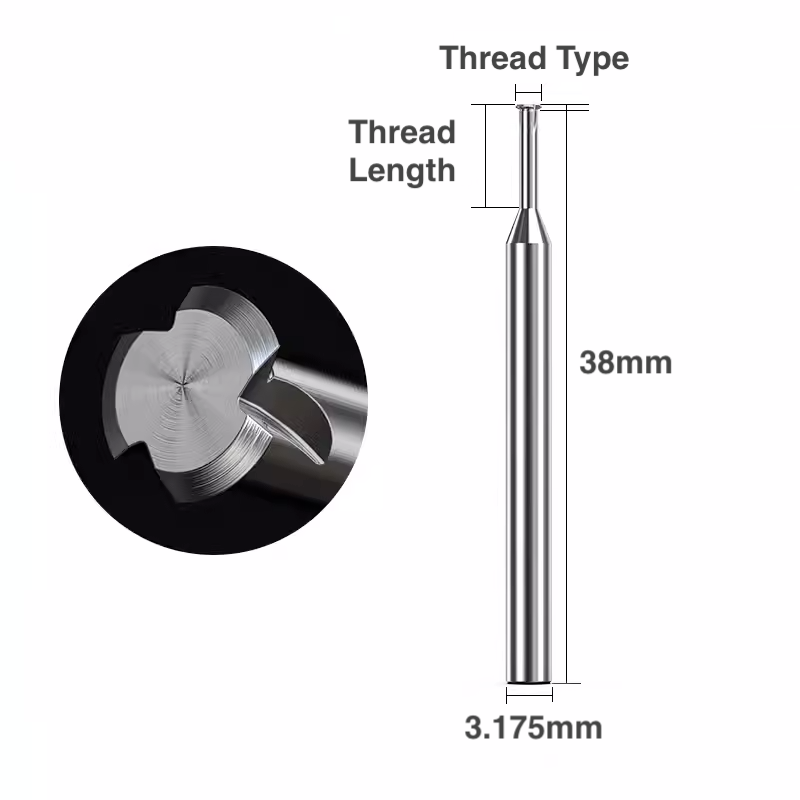

Tool Reference Parameters:

* RPM: SpindleSpeed(RPM) / Feed: FeedRate(mm/min)

PFeed: PlungeFeedRate(mm/min) / DOC: Depth of Cut(mm)

PFeed: PlungeFeedRate(mm/min) / DOC: Depth of Cut(mm)

|

Nominal Size (Thread Milling) |

Thread Pitch (Thread Milling) |

Tapping Drill Size (Thread Milling) |

Woods & Plastics (Speed & Feed) |

Metals (Speed & Feed) |

Composites (Speed & Feed) |

|---|---|---|---|---|---|

| M1 | 0.25 | 0.75mm |

RPM:10000 Feed:200 DOC:0.25 |

RPM:12000 Feed:100 DOC:0.25 |

RPM:10000 Feed:150 PFeed:150 DOC:0.25 |

| M2 | 0.4 | 1.6mm |

RPM:10000 Feed:300 PFeed:300 DOC:0.4 |

RPM:12000 Feed:150 PFeed:150 DOC:0.4 |

RPM:10000 Feed:200 PFeed:200 DOC:0.4 |

| M2.5 | 0.45 | 2.05mm |

RPM:10000 Feed:300 PFeed:300 DOC:0.45 |

RPM:12000 Feed:150 PFeed:150 DOC:0.45 |

RPM:10000 Feed:200 PFeed:200 DOC:0.45 |

| M3 | 0.5 | 2.5mm |

RPM:10000 Feed:300 PFeed:300 DOC:0.5 |

RPM:12000 Feed:200 PFeed:200 DOC:0.5 |

RPM:10000 Feed:250 PFeed:250 DOC:0.5 |

| M4 | 0.7 | 3.3mm |

RPM:10000 Feed:300 PFeed:300 DOC:0.7 |

RPM:12000 Feed:200 PFeed:200 DOC:0.7 |

RPM:10000 Feed:300 PFeed:300 DOC:0.7 |

| M5 | 0.8 | 4.2mm |

RPM:10000 Feed:300 PFeed:300 DOC:0.8 |

RPM:12000 Feed:200 PFeed:200 DOC:0.8 |

RPM:10000 Feed:300 PFeed:300 DOC:0.8 |