Carvera 데스크탑 CNC 기계

올해의 마지막 특가 세일

사은품 + 즉시 할인

자주 구매하는 패키지

무료 해운 ~을 위한 명령 ~ 위에 100달러

30일 반품

1 년도 보증

자세히 알아보기:

-

Carvera 개봉하기: 시작할 준비가 되셨나요? 새로운 CNC 기계에 포함된 모든 것과 손쉽게 설정하는 방법을 확인하려면 개봉 문서를 확인하세요. -

사용자 매뉴얼: 자세한 안내를 원하시면, 포괄적인 매뉴얼을 다운로드하여

Carvera CNC의 모든 기능과 특징을 안내받아 기계를 최대한 활용하세요. -

지식 공유: 창의적인 커뮤니티에 참여하여 지식 공유 섹션에서 만나보세요! 여기에서

Carvera 및Carvera Air CNC 기계를 사용한 감산 제조와 관련된 프로젝트, 파일 및 수업을 찾을 수 있습니다.

DIY 기술을 향상시키고 싶거나 흥미로운 새로운 프로젝트를 시작하고 싶다면,

참고:

1. 패키지는

2. 기계에는 이미 사용 가능한 무선 프로브가 하나 포함되어 있습니다. 하지만 원하신다면 백업용으로 하나 더 준비하실 수 있습니다.

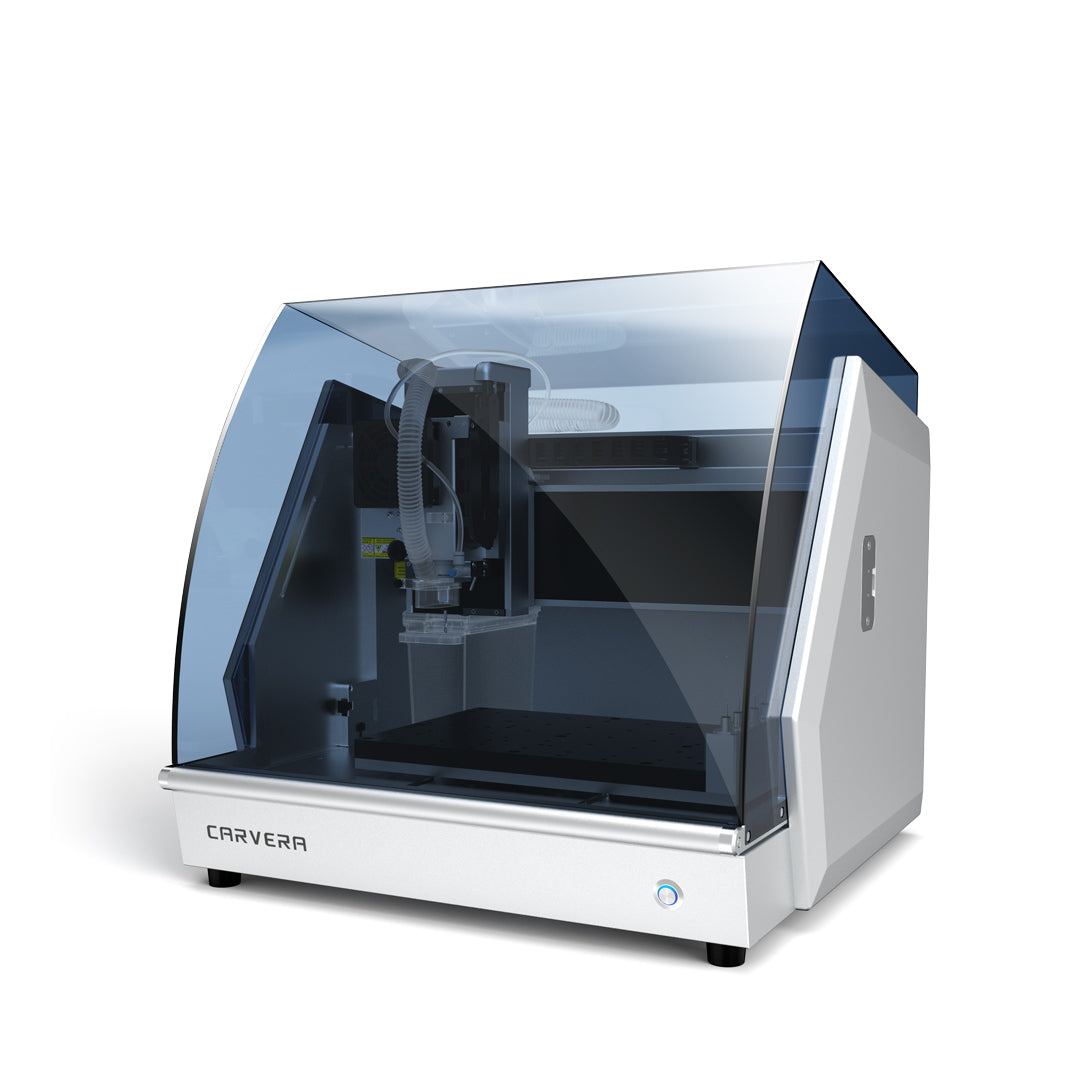

Carvera 데스크톱 CNC 머신

가장 스마트한 데스크톱 CNC

Machine almost any material

Your Project. Your Material. Carvera's Capability.

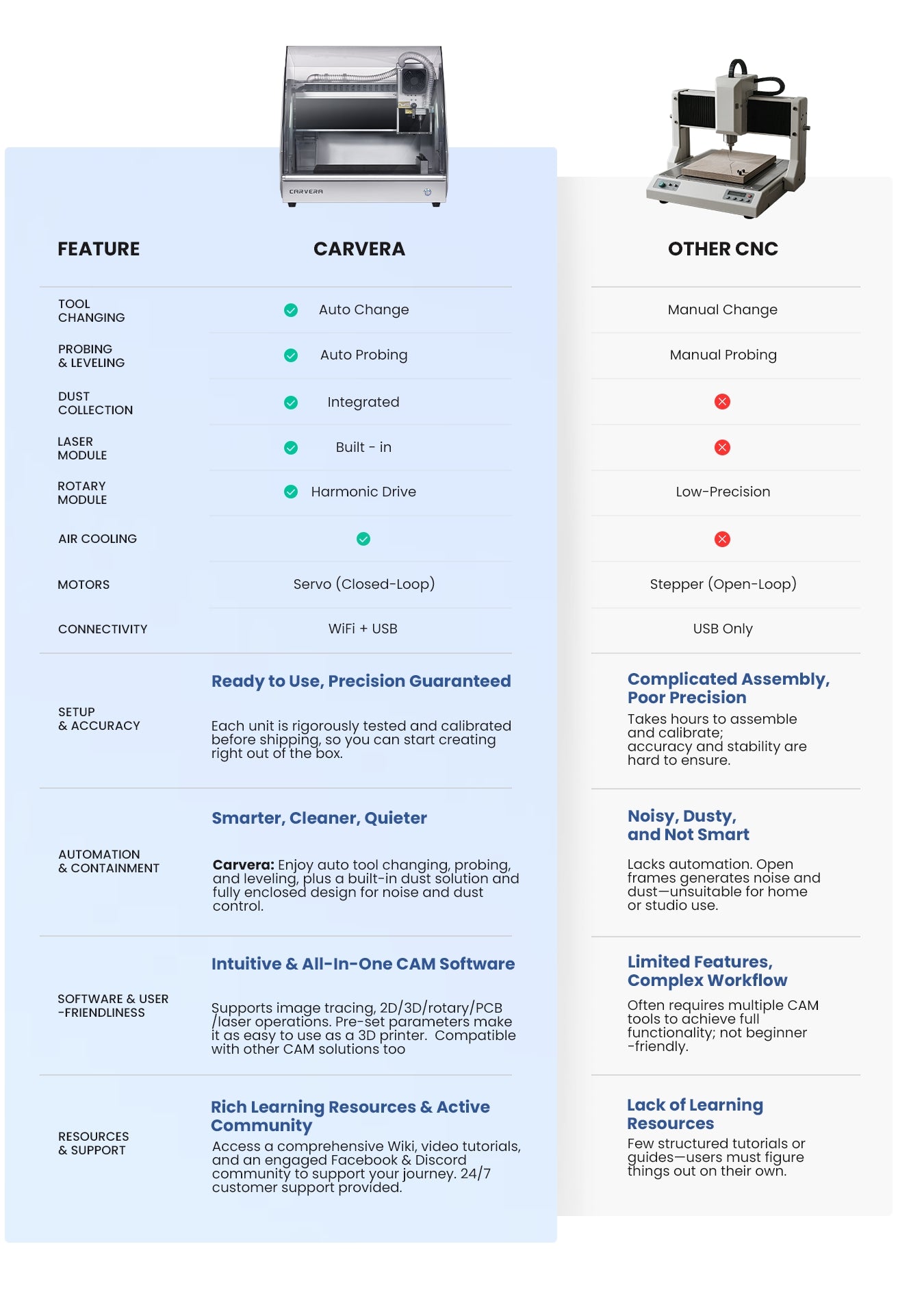

자동 도구 교체 및 자동 프로빙

자동 기능이 없으면 매 작업마다 모든 공구를 수동으로 교체하고 프로빙 작업도 수동으로 해야 하는데, 이는 PCB나 기타 복잡한 물체를 밀링할 때 매우 지루하고 시간이 많이 소요됩니다. 자동 레벨링, 절단, 세척 등 어떤 작업을 하든

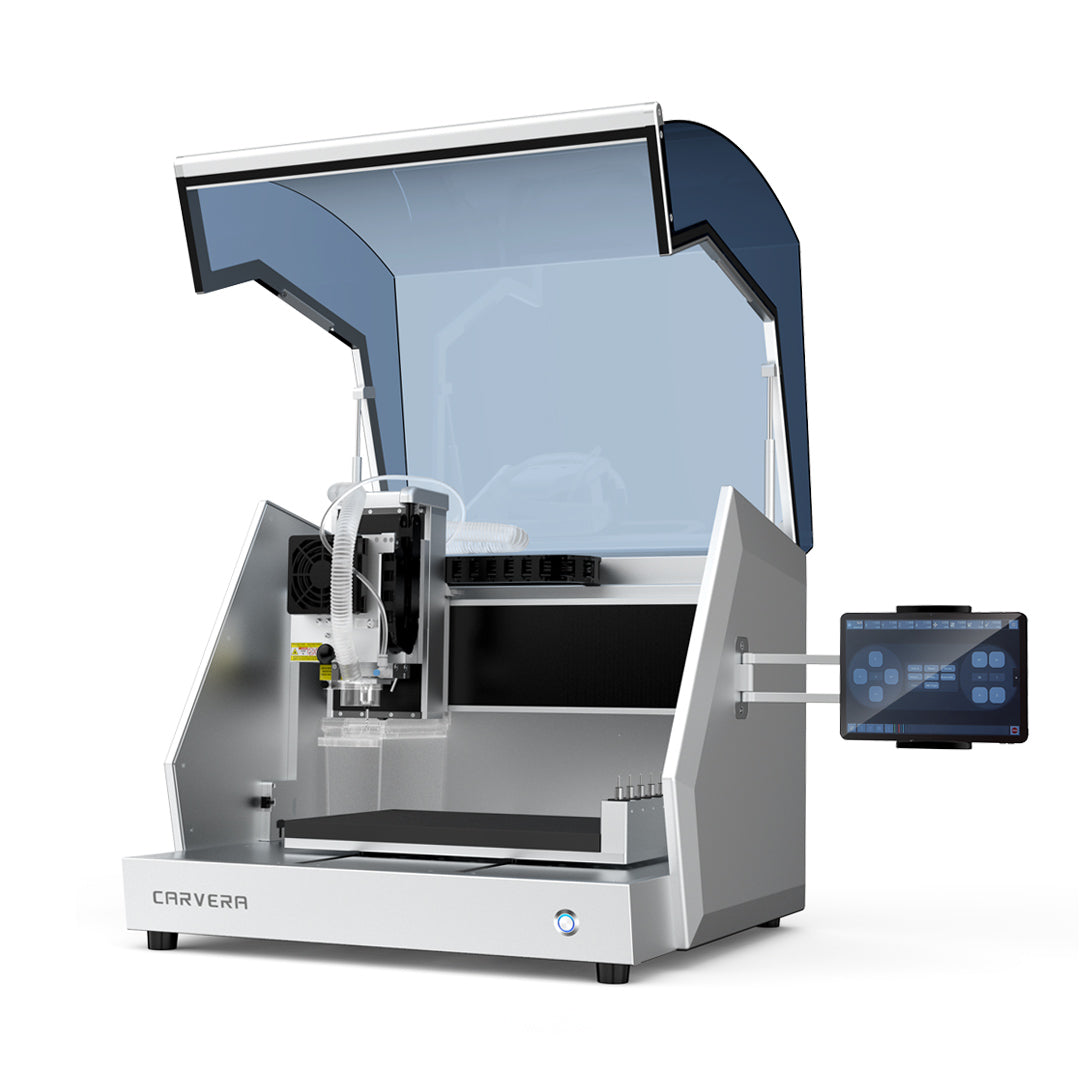

내장 먼지

수집

일반적으로 데스크톱 CNC 기계는 크기와 공간 제약으로 인해 집진 기능이 탑재되지 않습니다. 하지만 저희는 매우 혁신적인 방식으로 기계 내부에 집진 시스템을 완벽하게 구축하여 프로젝트를 깨끗하게 시작하고 깨끗하게 마무리할 수 있도록 지원합니다.

통합

레이저 모듈

레이저 각인은 제품에 아름다운 무늬를 새겨 넣을 수 있는 독특하고 놀라운 기술입니다. 2.5W 다이오드 레이저 모듈이 내장되어 있어 CNC와 CNC 사이를 원활하게 전환할 수 있습니다.

옵션 4축 모듈

4축 모듈을 사용하면 축이 하나 더 늘어나 가능성이 더욱 넓어지며 원통형 품목, 양면 물체, 3D 형상을 가공할 수 있습니다.

무한한 가능성

전자제품용 전문 PCB 제작

로봇을 위한 강력한 부품을 만드세요

예술을 만들다

유용한 것들을 만들어 보세요

탄소 섬유나 로봇용 금속 부품으로 최첨단 드론을 제작하는 사람들에게 CNC 밀링보다 더 나은 대안은 없습니다.

이러한 고급 부품은 3D 프린팅이 불가능하고 주문 제작이 필요한 경우가 많으며, 이는 프로토타입을 제작하거나 맞춤형 제품을 제작하는 데 비용이 많이 드는 방법이 될 수 있습니다.

보석부터 고급 목재, 주조 가능한 몰드까지 선택의 폭이 무궁무진합니다. 그리고

와 함께

당신이 어떤 종류의 메이커이든,

높은 품질과 정밀성

With 0.01mm resolution and <0.01mm spindle runout, precision forms Carvera's anatomy, engineered into every component from the ground up.

Empower schools with all-round support

Carefully Picked Example Projects

The Carvera is ready for out-of-the-box operation. We provide carefully curated example projects, enabling you to start creating from day one and learn CNC machining step-by-step.

Rich Learning Resources

Makera offers a comprehensive wiki and step-by-step YouTube tutorials with expert‑crafted resources. You can also join the Makera Community to explore, learn, and share with thousands of active fellow makers.

Amazingly Simple CAM Software

Makera CAM simplifies CNC strategies with built-in recommended parameters, making CNC programming surprisingly intuitive and remarkably easy to learn — at no cost for Makera users.

24/7 Support

Stuck on a problem you can’t solve with our resources? Makera has your back! Contact our 24/7 support team, and we’ll work with you to get it solved.

상자 안에 무엇이 들어있나요?

전문가들은 무엇이라고 말하나요?

247인쇄

"돈을 들인 만큼 많은 것을 얻을 수 있습니다. 자동화, 견고성, 신뢰도, 안정성이 뛰어나며, 많은 액세서리, 잘 안내된 예시 프로젝트 및 튜토리얼을 통해 시작할 수 있고, 바로 사용할 수 있습니다.

.”

낯선 사람들

"견고하고 바로 사용할 수 있는 데스크톱 CNC 밀링 머신을 찾고 있다면 이 제품이 딱입니다. 이 제품을 사용하게 되어 정말 만족스럽고, 앞으로 작업장에서 자주 사용하는 도구가 될 것 같습니다."

"자동 도구 교환기, 무선 터치 프로브 및 4축은 놀라운 수준의 자동화를 원활하게 제공합니다.

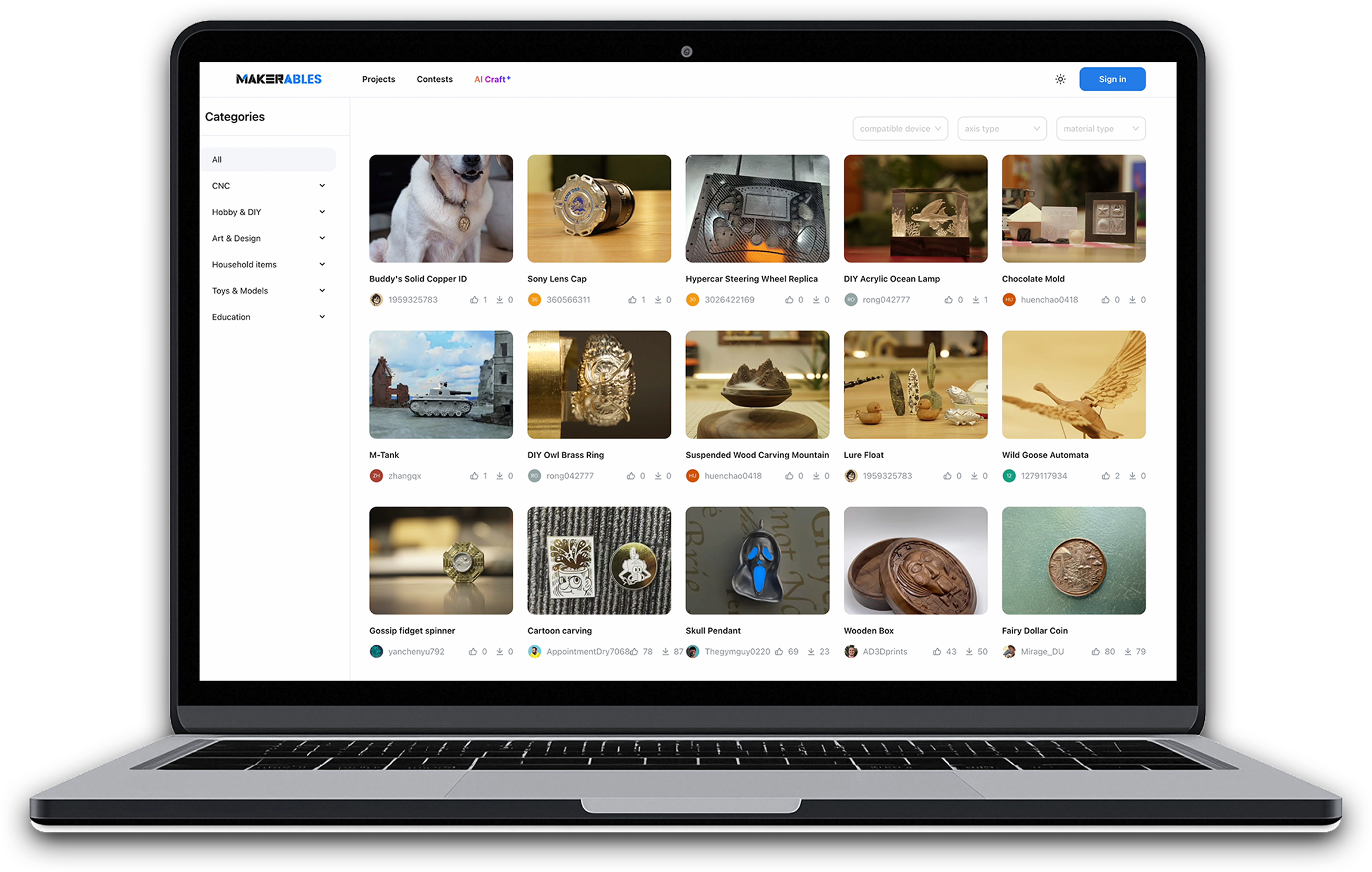

Explore a World of Designs

Makerables, Makera's CNC Project Sharing Platform. 3D printing already has mature sharing platforms. CNC deserves one too, so we built it.

AI-Powered Workflow

Customize CNC Models with Zero Modeling Skills. Experience the AI-powered workflow and create stunning crafts like a pro. (Available late this year to all Makera users)

명세서

-

Work Area36cm(X) * 24cm(Y) * 14cm(Z) / 14.2in * 9.4in * 5.5in

-

4th Axis Work Area (optional)9.2cm(Diameter) * 24cm(Length) / 3.6in * 9.4in

-

Gantry Clearance12cm / 4.7in

-

Max Height (Lid open)84cm / 33in

-

Footprint22.8in * 20.5in * 21.3in

-

Weight50kg / 110lbs (approx)

-

Power200 watt

-

Speed0 - 15000 RPM with closed-loop control

-

ColletCustom collet with 1/8in integrated (optional: 1/4in, 6mm, 4mm)

-

Tool Change MethodAuto Tool Changer

-

Tool library size6

-

CoolingAir cooling

-

Air AssistSupports External Air Compressor Connection

-

MotorServo motors for X/Y/Z axis, Nema17 stepper motor for A axis

-

Drive MethodBall screws with linear rails

-

Max Travel Speed6000mm / 236in per minute

-

4th Axis Drive Method (Optional)Harmonic drive

-

Spindle RunoutLess than 0.01mm / 0.0004in

-

Resolution0.01mm / 0.0004in

-

Power2.5 Watt

-

Laser Type445nm semiconductor diode laser

-

Dust controlInternal Dust Collection System

-

Dust tank volume0.8 liter

-

Makera Cyclone Dust Collector (Optional)Optional accessory

-

MetalIdeal for Aluminum, brass, copper. Compatible with Limitations: Steel, Titanium (not advised for prolonged processing)

-

WoodHardwoods, softwoods, MDF, plywoods, etc.

-

PlasticFoam, PVC, ABS, Acrylic, PC, HDPE, etc.

-

Composite materialCarbon fiber, FR4, etc.

-

Laser engrave materialWood, plastic, fabric, leather, cardboard, etc.

-

ControllerDedicated software supports CARVERA functions. New Makera Controller mobile app, which lets you control and monitor your machine remotely will be available late this year

-

Controller connectivityUSB / WIFI

-

Controller OSiOS, Andriod, Mac OS, Windows, Linux, etc.

-

Dedicated CAM softwareMakera CAM. Makera Stuido-the new Makera CAM will be avaliable free to all Makera users late this year

-

Compatible CAD/CAM softwareFusion360, SolidWorks, AutoCad, VCarve Pro, Aspire, Illustrator, etc.

-

MakerablesA universal CNC project-sharing platform from Makera. (Avaliable late this year.)

-

AI CraftMakera's AI tool lets you Customize CNC Models with Zero Modeling Skills.