Carvera Macchina CNC da tavolo

Pacchetto acquistato di frequente

Free Shipping for orders over $100

30-Day Return

1 Year Warranty

Esplora di più:

-

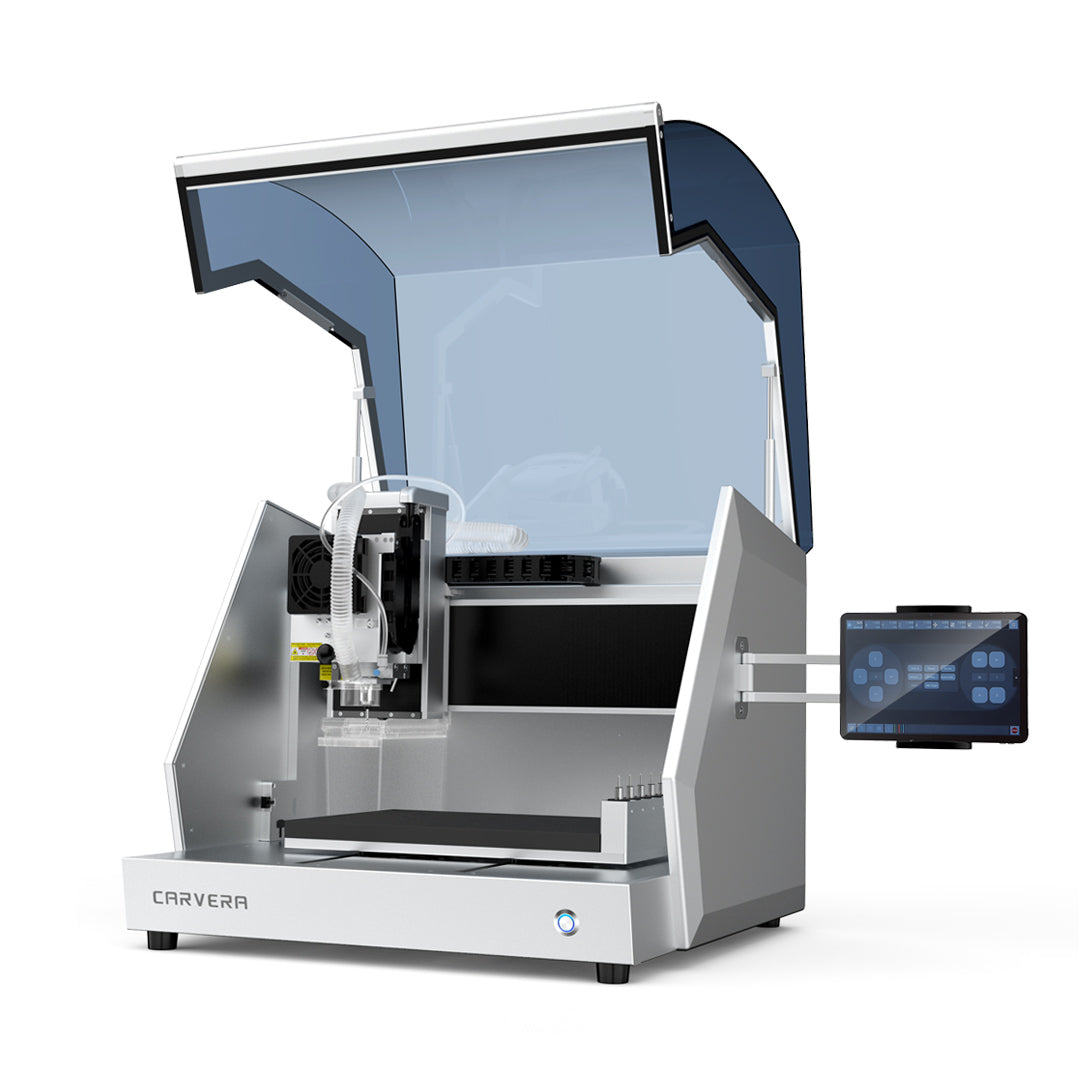

Disimballaggio

Carvera : Pronto a tuffarti? Dai un'occhiata al nostro Disimballa documento per vedere tutto ciò che la tua nuova macchina CNC include e come impostarla senza sforzo. -

Manuale Utente: Per una guida dettagliata, scarica il nostro completo manuale che ti guida attraverso ogni caratteristica e funzione della tua

Carvera CNC, assicurandoti di ottenere il massimo dalla tua macchina. -

Condivisione della Conoscenza: Unisciti alla nostra comunità creativa nella sezione Condivisione della Conoscenza! Troverai progetti, file e lezioni per interagire con la produzione sottrattiva utilizzando le

Carvera eCarvera Air Macchine CNC.

Se desideri migliorare le tue abilità nel fai-da-te o intraprendere nuovi progetti entusiasmanti,

Nota:

1. Il pacchetto è il

2. È già inclusa una sonda wireless nella macchina per l'uso immediato. Ma puoi preparare una di riserva se lo desideri.

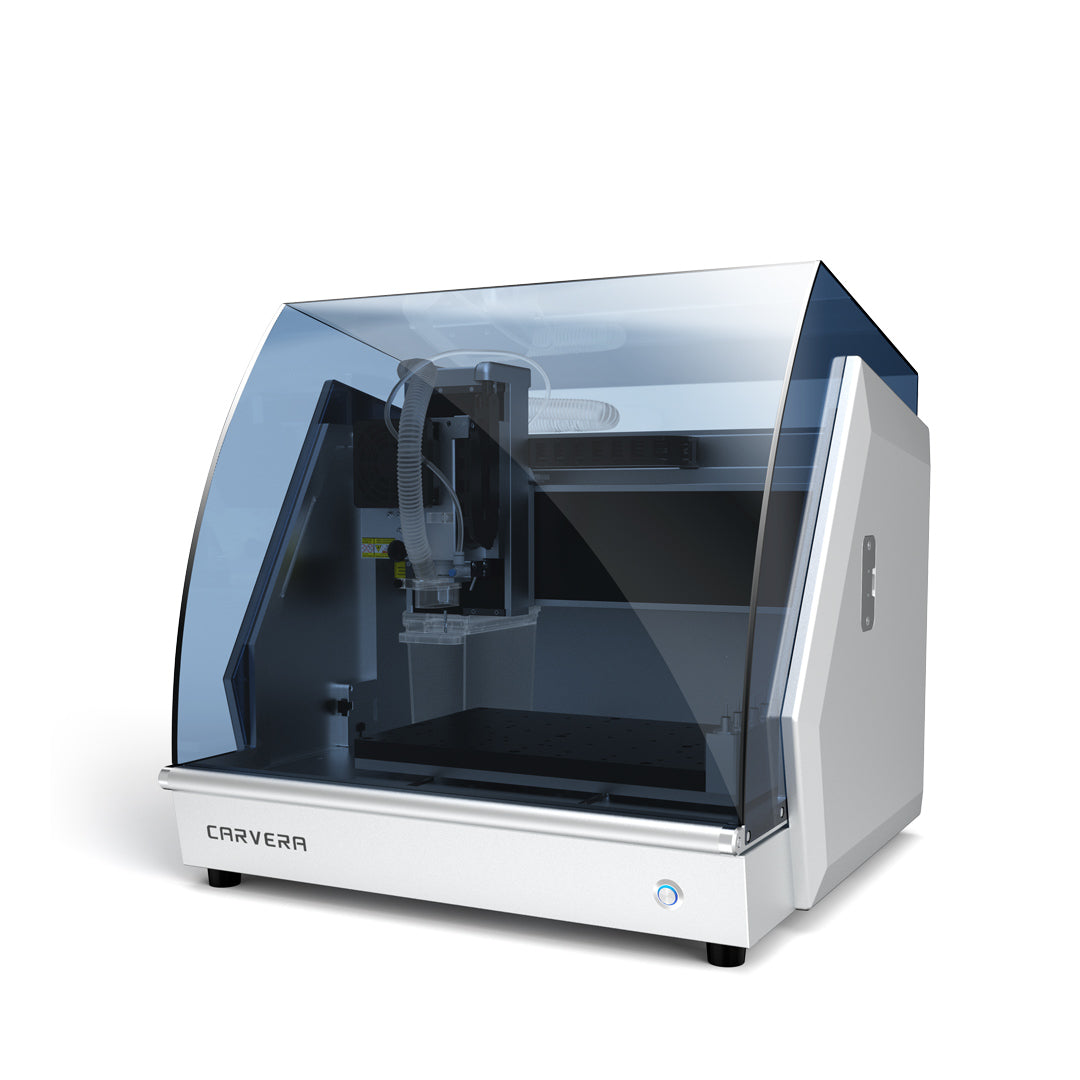

Carvera Macchina CNC da tavolo

Il CNC da tavolo più intelligente

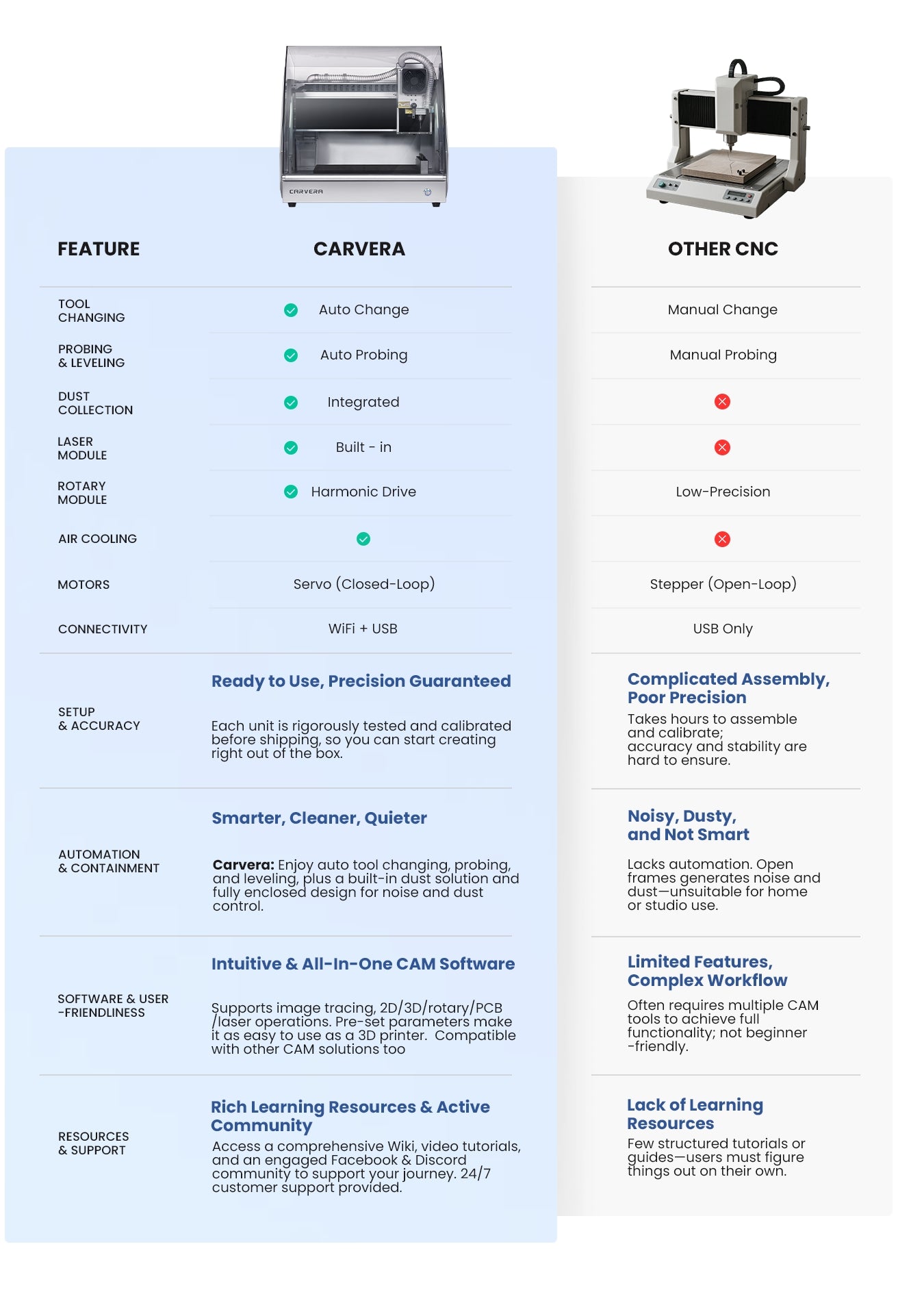

Cambio automatico dell'utensile e tastatura automatica

Senza le funzioni automatiche, è necessario cambiare manualmente ogni utensile durante ogni lavoro ed eseguire manualmente il lavoro di ispezione, il che è molto noioso e richiede tempo quando si fresano PCB o altri oggetti complessi. Che si tratti di autolivellamento, taglio, pulizia,

sistema di taglio,sistema di taglioRaccolta della polvere

incorporata

Normalmente, le macchine CNC da tavolo non sono dotate di funzioni di raccolta della polvere a causa delle dimensioni e dello spazio limitato. Grazie a un metodo molto innovativo, abbiamo costruito il sistema di raccolta delle polveri all'interno della macchina, per consentire ai vostri progetti di iniziare e finire in modo pulito.

Modulo laser

integrato

L'incisione laser è una tecnologia unica e sorprendente che consente di lasciare il segno e di disegnare bellissimi motivi sui prodotti. Con il modulo laser a diodi da 2,5 W integrato, è possibile passare senza problemi dal CNC al

Modulo opzionale per il 4° asse

Un asse in più, molte più possibilità: con il modulo 4° asse, è possibile lavorare oggetti cilindrici, bifacciali e forme 3D.

Possibilità infinite

Realizzate PCB professionali per i vostri prodotti elettronici

Creare parti resistenti per i vostri robot

Fare arte

Creare cose utili

Per chi costruisce droni all'avanguardia in fibra di carbonio o parti metalliche per i propri robot, non c'è alternativa alla fresatura CNC.

Queste parti di fascia alta non possono essere stampate in 3D e spesso devono essere realizzate su ordinazione, il che può essere un modo costoso per prototipare o costruire prodotti personalizzati. Con

Le opzioni sono infinite, dai gioielli ai legni pregiati agli stampi colabili. E poiché

Con

Non importa che tipo di creatore siate,

Alta qualità e precisione

Cosa c'è nella scatola

Cosa dicono gli esperti?

247printing

"Si ottiene molto per i soldi spesi: molta automazione, molta robustezza, molta sicurezza e affidabilità, una tonnellata di accessori, progetti di esempio e tutorial ben guidati per iniziare e per essere istruiti fin dalla scatola

"

Parti estranee

"Se state cercando una fresa CNC da tavolo solida e funzionante, questa è un'ottima opzione. Sono davvero felice di averla e diventerà uno strumento abituale qui in officina"

"Il cambio utensile automatico, la sonda a contatto wireless e il quarto asse apportano un'incredibile quantità di automazione al CNC

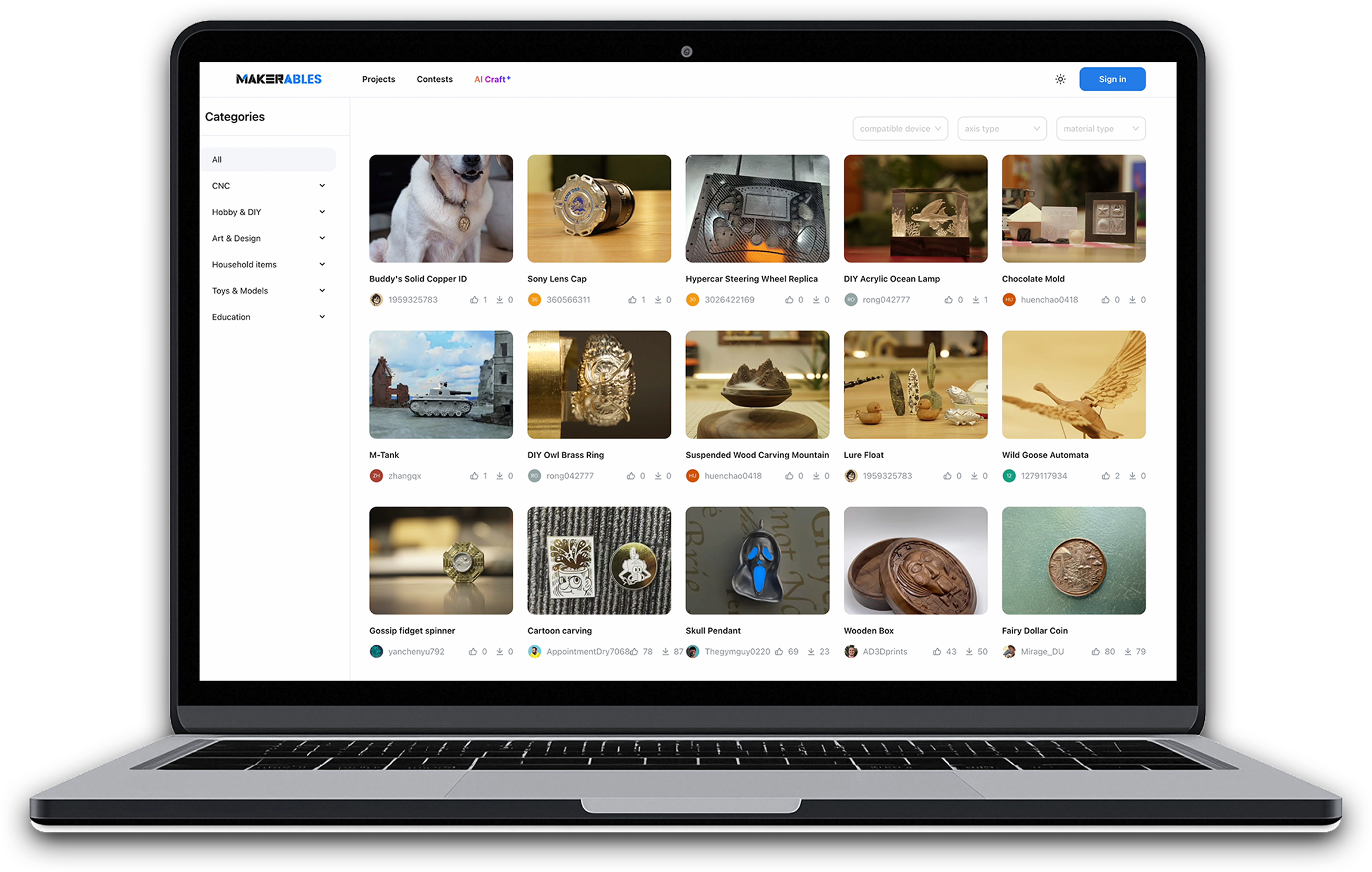

Explore a World of Designs

Makerables, Makera's CNC Project Sharing Platform. 3D printing already has mature sharing platforms. CNC deserves one too, so we built it.

AI-Powered Workflow

Customize CNC Models with Zero Modeling Skills. Experience the AI-powered workflow and create stunning crafts like a pro. (Available late this year to all Makera users)

Specifiche

-

Work Area36cm(X) * 24cm(Y) * 14cm(Z) / 14.2in * 9.4in * 5.5in

-

4th Axis Work Area (optional)9.2cm(Diameter) * 24cm(Length) / 3.6in * 9.4in

-

Gantry Clearance12cm / 4.7in

-

Max Height (Lid open)84cm / 33in

-

Footprint22.8in * 20.5in * 21.3in

-

Weight50kg / 110lbs (approx)

-

Power200 watt

-

Speed0 - 15000 RPM with closed-loop control

-

ColletCustom collet with 1/8in integrated (optional: 1/4in, 6mm, 4mm)

-

Tool Change MethodAuto Tool Changer

-

Tool library size6

-

CoolingAir cooling

-

Air AssistSupports External Air Compressor Connection

-

MotorServo motors for X/Y/Z axis, Nema17 stepper motor for A axis

-

Drive MethodBall screws with linear rails

-

Max Travel Speed6000mm / 236in per minute

-

4th Axis Drive Method (Optional)Harmonic drive

-

Spindle RunoutLess than 0.01mm / 0.0004in

-

Resolution0.01mm / 0.0004in

-

Power2.5 Watt

-

Laser Type445nm semiconductor diode laser

-

Dust controlInternal Dust Collection System

-

Dust tank volume0.8 liter

-

Makera Cyclone Dust Collector (Optional)Optional accessory

-

MetalIdeal for Aluminum, brass, copper. Compatible with Limitations: Steel, Titanium (not advised for prolonged processing)

-

WoodHardwoods, softwoods, MDF, plywoods, etc.

-

PlasticFoam, PVC, ABS, Acrylic, PC, HDPE, etc.

-

Composite materialCarbon fiber, FR4, etc.

-

Laser engrave materialWood, plastic, fabric, leather, cardboard, etc.

-

ControllerDedicated software supports CARVERA functions. New Makera Controller mobile app, which lets you control and monitor your machine remotely will be available late this year

-

Controller connectivityUSB / WIFI

-

Controller OSiOS, Andriod, Mac OS, Windows, Linux, etc.

-

Dedicated CAM softwareMakera CAM. Makera Stuido-the new Makera CAM will be avaliable free to all Makera users late this year

-

Compatible CAD/CAM softwareFusion360, SolidWorks, AutoCad, VCarve Pro, Aspire, Illustrator, etc.

-

MakerablesA universal CNC project-sharing platform from Makera. (Avaliable late this year.)

-

AI CraftMakera's AI tool lets you Customize CNC Models with Zero Modeling Skills.