Carvera Desktop-CNC-Maschine

Häufig gekauftes Paket

Free Shipping for orders over $100

30-Day Return

1 Year Warranty

Mehr entdecken:

-

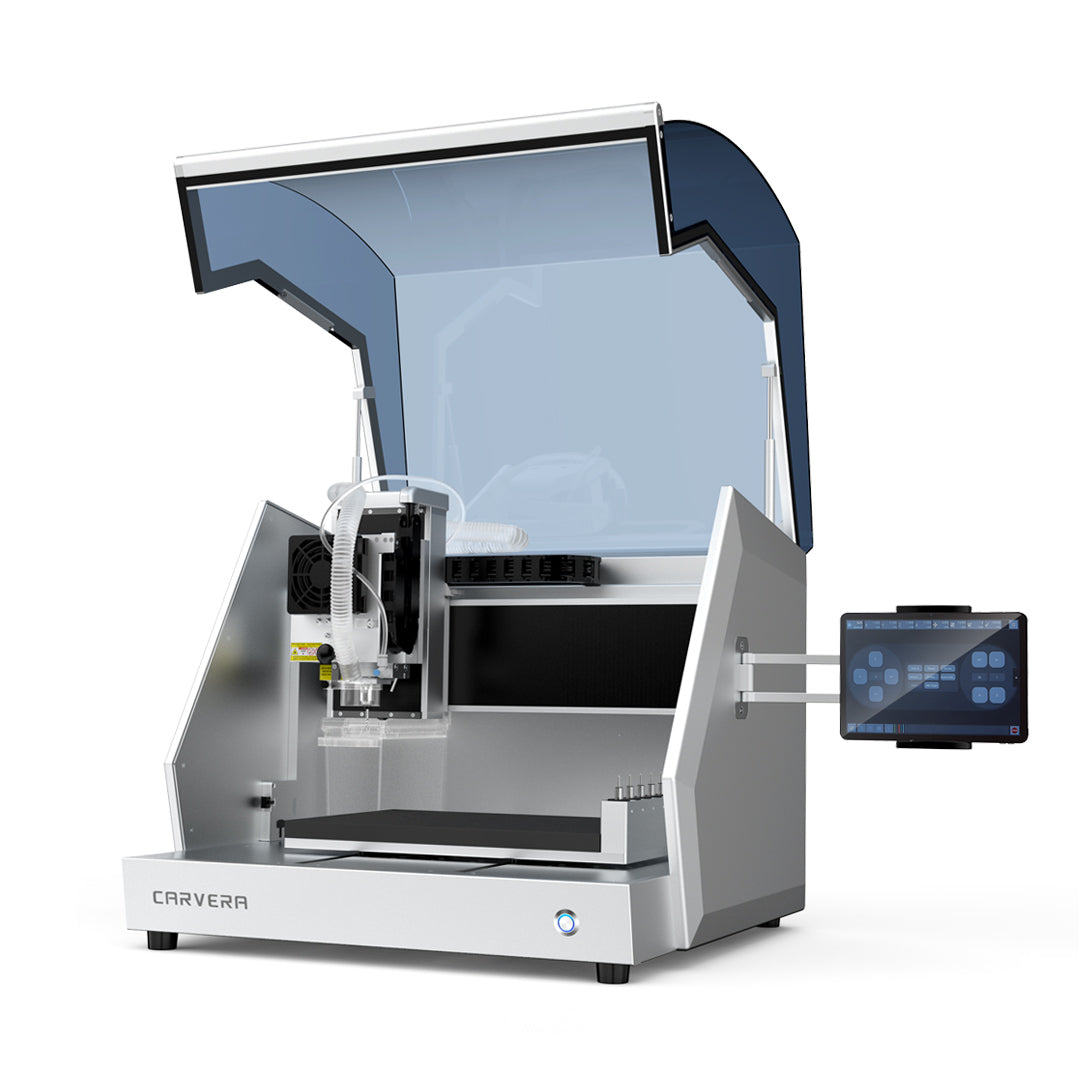

Auspacken von

Carvera : Bereit, einzutauchen? Schauen Sie sich unser Auspacken Dokument an, um alles zu sehen, was Ihre neue CNC-Maschine enthält und wie Sie sie mühelos einrichten können. -

Benutzerhandbuch: Für detaillierte Anleitungen laden Sie unser umfassendes Handbuch herunter, das Sie durch jede Funktion und Eigenschaft Ihrer

Carvera CNC führt und sicherstellt, dass Sie das Beste aus Ihrer Maschine herausholen. -

Wissensaustausch: Treten Sie unserer kreativen Gemeinschaft im Wissensaustausch Bereich bei! Sie finden Projekte, Dateien und Lektionen zur Auseinandersetzung mit subtraktiver Fertigung unter Verwendung der

Carvera undCarvera Air CNC-Maschinen.

Ob Sie Ihre DIY-Fähigkeiten verbessern oder aufregende neue Projekte starten möchten,

Hinweis:

1. Das Paket ist das

2. Es ist bereits eine drahtlose Sonde in der Maschine enthalten, die Sie sofort verwenden können. Aber Sie können nach Belieben eine Backup-Sonde vorbereiten.

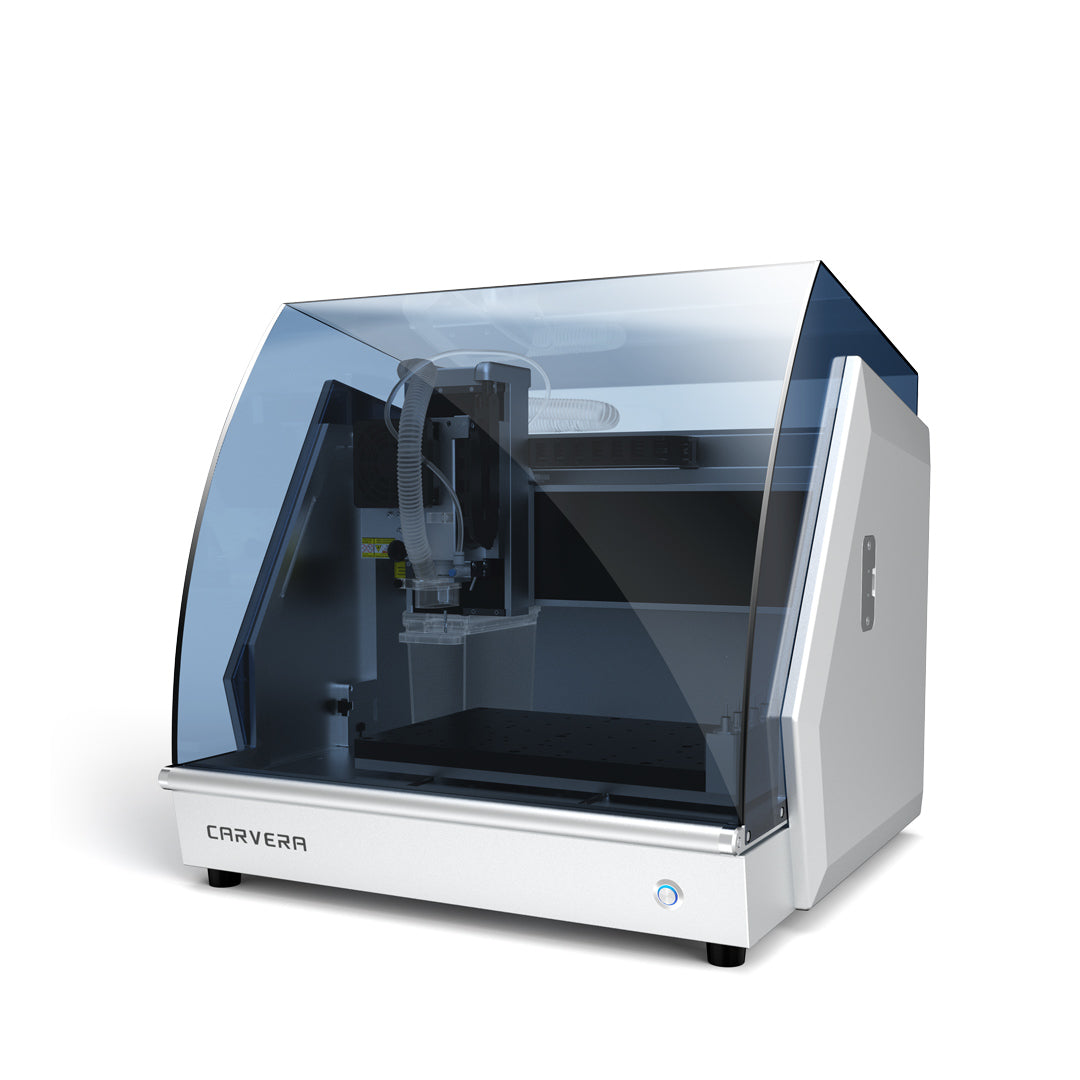

Carvera Desktop-CNC-Maschine

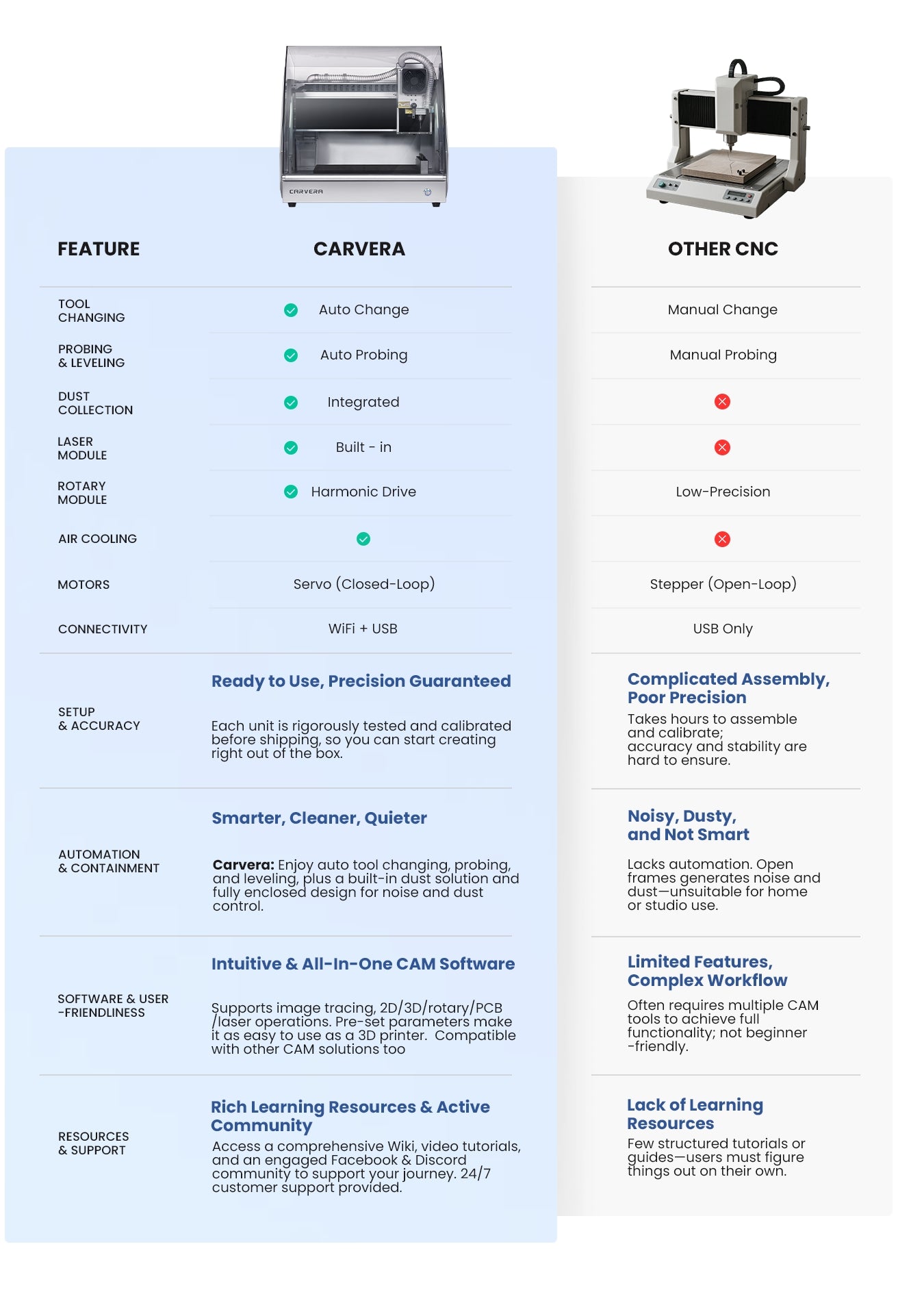

Die intelligenteste Desktop-CNC

Automatischer Werkzeugwechsel und automatisches Antasten

Ohne die automatischen Funktionen müssen Sie bei jedem Auftrag jedes Werkzeug manuell wechseln und die Antastarbeiten manuell durchführen, was beim Fräsen von Leiterplatten oder anderen komplexen Objekten sehr mühsam und zeitaufwendig ist. Ob Sie nun automatisch nivellieren, schneiden, reinigen,

Eingebaute Staub

Absaugung

Normalerweise sind Desktop-CNC-Maschinen nicht mit Staubabsaugung Funktionen wegen der Größe und begrenzten Raum ausgestattet. Durch eine sehr innovative Art und Weise haben wir das Staubsammelsystem komplett in die Maschine eingebaut, damit Ihre Projekte sauber beginnen und sauber enden können.

Integriertes

Lasermodul

Die Lasergravur ist eine einzigartige und erstaunliche Technologie, mit der Sie Ihre Spuren hinterlassen und schöne Muster auf Ihr Produkt zeichnen können. Mit dem integrierten 2,5-W-Diodenlasermodul können Sie nahtlos zwischen CNC.

wechselnOptionales Modul für die 4. Achse

Eine Achse mehr, viel mehr Möglichkeiten, mit dem Modul der 4. Achse können Sie zylindrische Gegenstände, doppelseitige Objekte und 3D-Formen bearbeiten.

Unendliche Möglichkeiten

Erstellen Sie professionelle Leiterplatten für Ihre Elektronik

Stelle starke Teile für deine Roboter her

Kunst machen

Nützliche Dinge herstellen

Für diejenigen, die hochmoderne Drohnen aus Kohlefaser oder Metallteile für ihre Roboter bauen, gibt es keinen Ersatz für das CNC-Fräsen.

Diese hochwertigen Teile können nicht in 3D gedruckt werden und müssen oft auf Bestellung gefertigt werden, was eine teure Art sein kann, Prototypen oder kundenspezifische Produkte zu bauen. Mit

Die Möglichkeiten sind endlos, von Schmuck über Edelhölzer bis hin zu gießbaren Formen. Und da

Mit

Egal, welche Art von Bastler du bist,

Hohe Qualität und Präzision

Was ist in der Box

Was sagen die Experten?

247drucken

"Man bekommt viel für sein Geld - viel Automatisierung, viel Robustheit, viel Vertrauen und Zuverlässigkeit, eine Menge Zubehör, gut angeleitete Beispielprojekte und Tutorials, damit man sofort loslegen kann."

Fremde Teile

"Wenn Sie nach einer soliden, sofort einsatzbereiten Desktop-CNC-Fräse suchen, ist dies eine großartige Option. Ich bin wirklich froh, dass ich sie habe, und sie wird ein regelmäßiges Werkzeug hier in der Werkstatt werden."

"Der automatische Werkzeugwechsler, der kabellose Messtaster und die 4. Achse bringen nahtlos ein unglaubliches Maß an Automatisierung in die

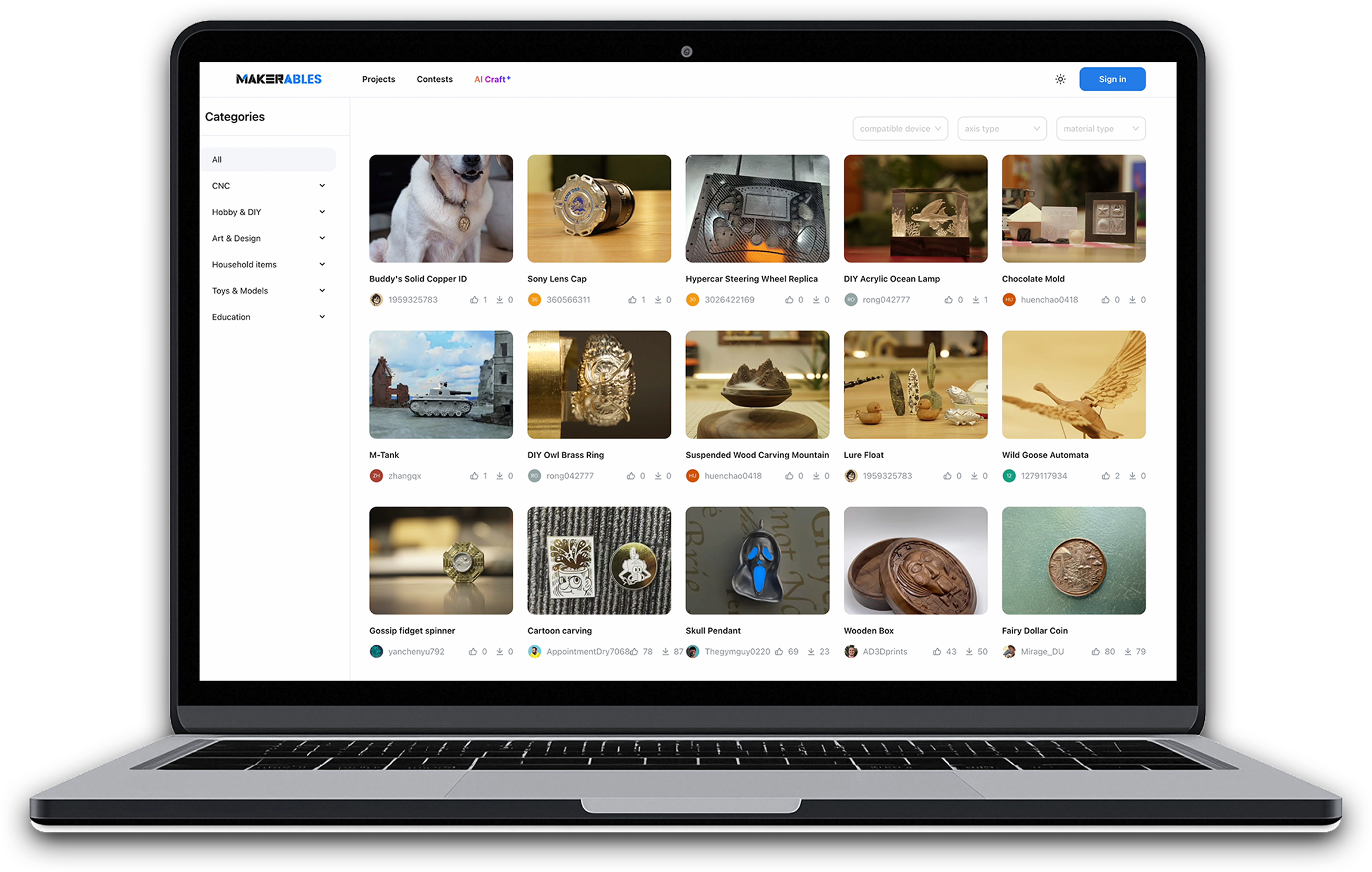

Explore a World of Designs

Makerables, Makera's CNC Project Sharing Platform. 3D printing already has mature sharing platforms. CNC deserves one too, so we built it.

AI-Powered Workflow

Customize CNC Models with Zero Modeling Skills. Experience the AI-powered workflow and create stunning crafts like a pro. (Available late this year to all Makera users)

Spezifikationen

-

Work Area36cm(X) * 24cm(Y) * 14cm(Z) / 14.2in * 9.4in * 5.5in

-

4th Axis Work Area (optional)9.2cm(Diameter) * 24cm(Length) / 3.6in * 9.4in

-

Gantry Clearance12cm / 4.7in

-

Max Height (Lid open)84cm / 33in

-

Footprint22.8in * 20.5in * 21.3in

-

Weight50kg / 110lbs (approx)

-

Power200 watt

-

Speed0 - 15000 RPM with closed-loop control

-

ColletCustom collet with 1/8in integrated (optional: 1/4in, 6mm, 4mm)

-

Tool Change MethodAuto Tool Changer

-

Tool library size6

-

CoolingAir cooling

-

Air AssistSupports External Air Compressor Connection

-

MotorServo motors for X/Y/Z axis, Nema17 stepper motor for A axis

-

Drive MethodBall screws with linear rails

-

Max Travel Speed6000mm / 236in per minute

-

4th Axis Drive Method (Optional)Harmonic drive

-

Spindle RunoutLess than 0.01mm / 0.0004in

-

Resolution0.01mm / 0.0004in

-

Power2.5 Watt

-

Laser Type445nm semiconductor diode laser

-

Dust controlInternal Dust Collection System

-

Dust tank volume0.8 liter

-

Makera Cyclone Dust Collector (Optional)Optional accessory

-

MetalIdeal for Aluminum, brass, copper. Compatible with Limitations: Steel, Titanium (not advised for prolonged processing)

-

WoodHardwoods, softwoods, MDF, plywoods, etc.

-

PlasticFoam, PVC, ABS, Acrylic, PC, HDPE, etc.

-

Composite materialCarbon fiber, FR4, etc.

-

Laser engrave materialWood, plastic, fabric, leather, cardboard, etc.

-

ControllerDedicated software supports CARVERA functions. New Makera Controller mobile app, which lets you control and monitor your machine remotely will be available late this year

-

Controller connectivityUSB / WIFI

-

Controller OSiOS, Andriod, Mac OS, Windows, Linux, etc.

-

Dedicated CAM softwareMakera CAM. Makera Stuido-the new Makera CAM will be avaliable free to all Makera users late this year

-

Compatible CAD/CAM softwareFusion360, SolidWorks, AutoCad, VCarve Pro, Aspire, Illustrator, etc.

-

MakerablesA universal CNC project-sharing platform from Makera. (Avaliable late this year.)

-

AI CraftMakera's AI tool lets you Customize CNC Models with Zero Modeling Skills.