Carvera Desktop CNC-machine

Veel gekocht pakket

Free Shipping for orders over $100

30-Day Return

1 Year Warranty

Ontdek Meer:

-

Uitpakken

Carvera : Klaar om erin te duiken? Bekijk ons Uitpak document om te zien wat er allemaal bij uw nieuwe CNC-machine is inbegrepen en hoe u deze moeiteloos kunt opzetten. -

Gebruikershandleiding: Voor gedetailleerde begeleiding, download onze uitgebreide handleiding die u door elke functie en eigenschap van uw

Carvera CNC leidt, zodat u het meeste uit uw machine haalt. -

Kennisdeling: Sluit je aan bij onze creatieve gemeenschap in de Kennisdeling sectie! Je vindt projecten, bestanden en lessen voor het werken met subtractieve productie met behulp van de

Carvera enCarvera Air CNC-machines.

Of je nu je doe-het-zelf vaardigheden wilt verbeteren of aan spannende nieuwe projecten wilt beginnen,

Opmerking:

1. Het pakket is de

2. Er is al één draadloze probe inbegrepen in de machine die je direct kunt gebruiken. Maar je kunt een reserve probe voorbereiden als je dat wilt.

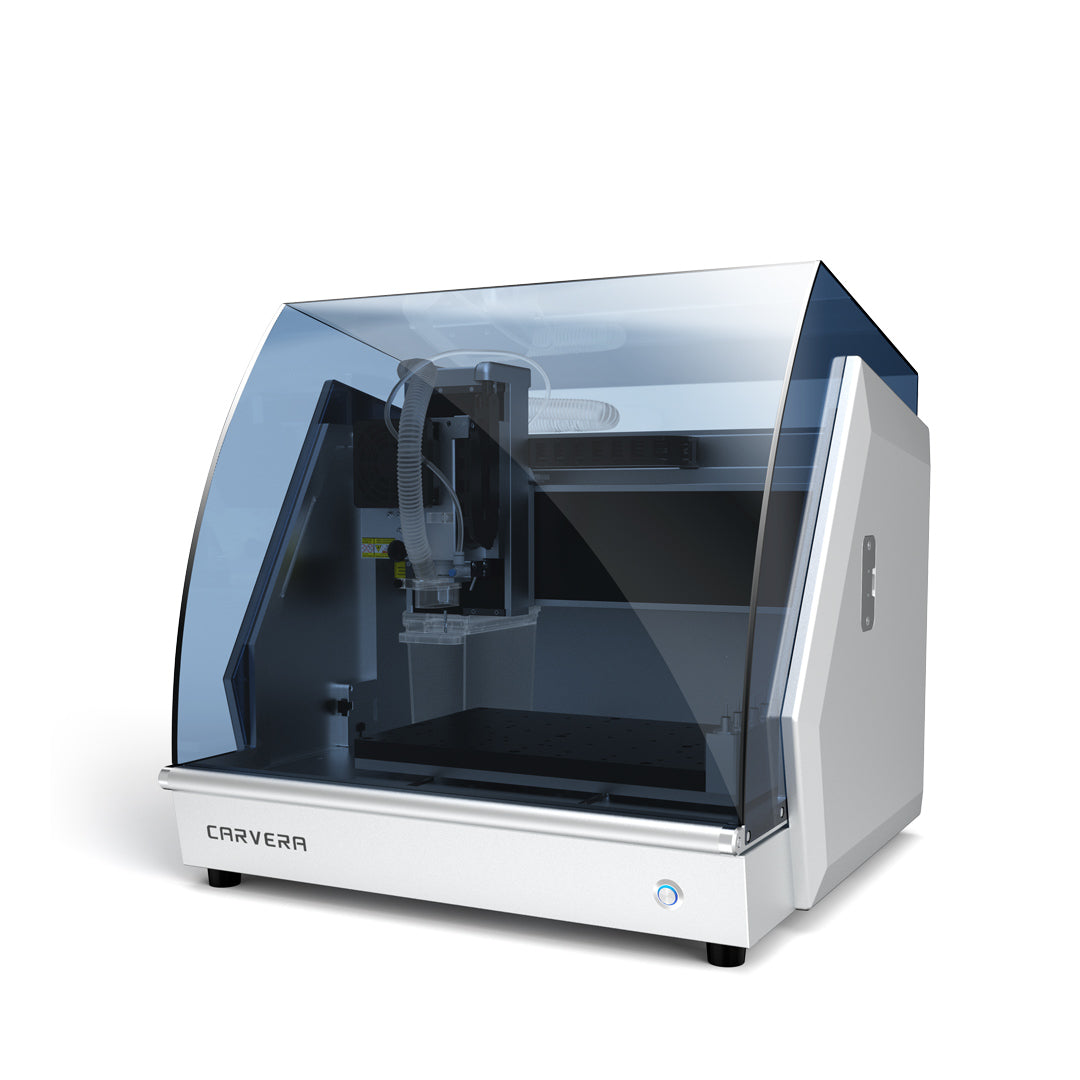

Carvera Desktop CNC machine

De slimste desktop CNC

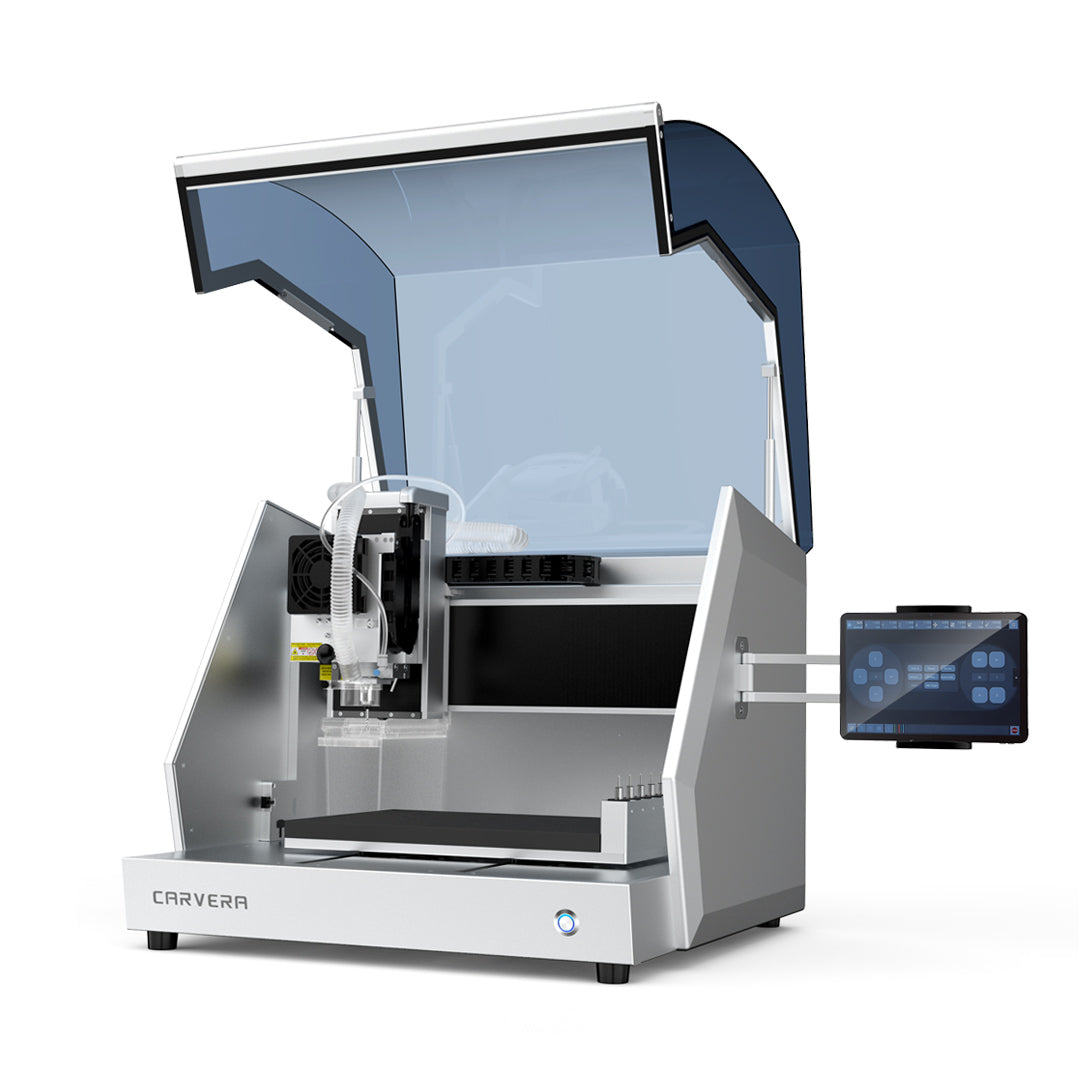

Automatisch gereedschap wisselen en automatisch tastertechniek

Zonder de automatische functies moet je elk gereedschap handmatig wisselen tijdens elke job en handmatig aftasten, wat erg vervelend en tijdrovend is bij het frezen van printplaten of andere complexe objecten. Of u nu automatisch nivelleert, snijdt, reinigt,

Ingebouwde stof

opvang

Normaal gesproken zijn desktop CNC machines niet uitgerust met stofopvangfuncties vanwege de grootte en beperkte ruimte. Op een zeer innovatieve manier hebben we het stofopvangsysteem volledig in de machine ingebouwd, zodat uw projecten schoon beginnen en schoon eindigen.

Geïntegreerde

lasermodule

Lasergraveren is een unieke en verbazingwekkende technologie waarmee je je stempel kunt drukken en prachtige patronen op je product kunt tekenen. Met de geïntegreerde 2,5 W diodelasermodule kun je naadloos schakelen tussen CNC.

Optionele 4e asmodule

Een as meer, veel meer mogelijkheden, met de module voor de 4e as kunt u cilindrische voorwerpen, dubbelzijdige voorwerpen en 3D-vormen bewerken.

Eindeloze mogelijkheden

Maak professionele printplaten voor uw elektronica

Maak sterke onderdelen voor je robots

Kunst maken

Maak nuttige dingen

Voor degenen die geavanceerde drones bouwen van koolstofvezel of metalen onderdelen voor hun robots, is er geen alternatief voor CNC-frezen.

Deze high-end onderdelen kunnen niet 3D-geprint worden en moeten vaak op bestelling gemaakt worden, wat een dure manier kan zijn om prototypes te maken of aangepaste producten te bouwen. Met

De mogelijkheden zijn eindeloos, van sieraden tot fijn hout tot gietbare mallen. En omdat

Met

Het maakt niet uit wat voor soort maker je bent,

Hoge kwaliteit en precisie

Wat zit er in de doos

Wat zeggen de experts?

247printing

"Je krijgt veel voor je geld - veel automatisering, veel stevigheid, veel vertrouwen en betrouwbaarheid, veel accessoires, goed begeleide voorbeeldprojecten en handleidingen om aan de slag te gaan en goed opgeleid uit de doos te komen

."

Vreemde onderdelen

"Als je op zoek bent naar een solide desktop CNC frees die meteen goed werkt, dan is dit een geweldige optie. Ik ben erg blij dat ik deze heb en het zal een vast gereedschap worden hier in de winkel."

"De automatische gereedschapwisselaar, draadloze schakelende meettaster en 4e as brengen naadloos een ongelooflijke hoeveelheid automatisering naar de

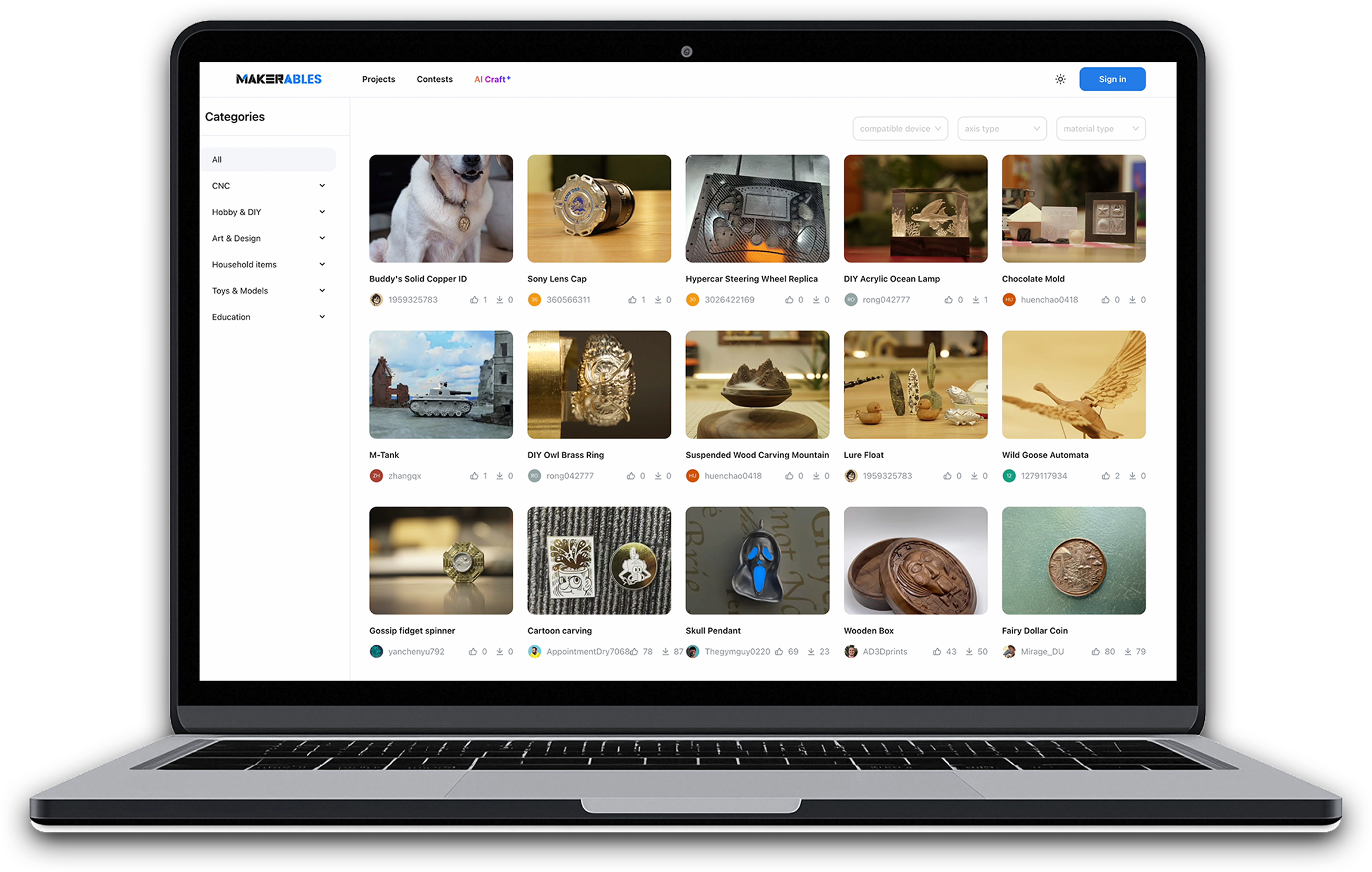

Explore a World of Designs

Makerables, Makera's CNC Project Sharing Platform. 3D printing already has mature sharing platforms. CNC deserves one too, so we built it.

AI-Powered Workflow

Customize CNC Models with Zero Modeling Skills. Experience the AI-powered workflow and create stunning crafts like a pro. (Available late this year to all Makera users)

Specificaties

-

Work Area36cm(X) * 24cm(Y) * 14cm(Z) / 14.2in * 9.4in * 5.5in

-

4th Axis Work Area (optional)9.2cm(Diameter) * 24cm(Length) / 3.6in * 9.4in

-

Gantry Clearance12cm / 4.7in

-

Max Height (Lid open)84cm / 33in

-

Footprint22.8in * 20.5in * 21.3in

-

Weight50kg / 110lbs (approx)

-

Power200 watt

-

Speed0 - 15000 RPM with closed-loop control

-

ColletCustom collet with 1/8in integrated (optional: 1/4in, 6mm, 4mm)

-

Tool Change MethodAuto Tool Changer

-

Tool library size6

-

CoolingAir cooling

-

Air AssistSupports External Air Compressor Connection

-

MotorServo motors for X/Y/Z axis, Nema17 stepper motor for A axis

-

Drive MethodBall screws with linear rails

-

Max Travel Speed6000mm / 236in per minute

-

4th Axis Drive Method (Optional)Harmonic drive

-

Spindle RunoutLess than 0.01mm / 0.0004in

-

Resolution0.01mm / 0.0004in

-

Power2.5 Watt

-

Laser Type445nm semiconductor diode laser

-

Dust controlInternal Dust Collection System

-

Dust tank volume0.8 liter

-

Makera Cyclone Dust Collector (Optional)Optional accessory

-

MetalIdeal for Aluminum, brass, copper. Compatible with Limitations: Steel, Titanium (not advised for prolonged processing)

-

WoodHardwoods, softwoods, MDF, plywoods, etc.

-

PlasticFoam, PVC, ABS, Acrylic, PC, HDPE, etc.

-

Composite materialCarbon fiber, FR4, etc.

-

Laser engrave materialWood, plastic, fabric, leather, cardboard, etc.

-

ControllerDedicated software supports CARVERA functions. New Makera Controller mobile app, which lets you control and monitor your machine remotely will be available late this year

-

Controller connectivityUSB / WIFI

-

Controller OSiOS, Andriod, Mac OS, Windows, Linux, etc.

-

Dedicated CAM softwareMakera CAM. Makera Stuido-the new Makera CAM will be avaliable free to all Makera users late this year

-

Compatible CAD/CAM softwareFusion360, SolidWorks, AutoCad, VCarve Pro, Aspire, Illustrator, etc.

-

MakerablesA universal CNC project-sharing platform from Makera. (Avaliable late this year.)

-

AI CraftMakera's AI tool lets you Customize CNC Models with Zero Modeling Skills.